A combustion analyzer is a crucial gas detection device that measures the levels of carbon monoxide (CO), oxygen (O2), and carbon dioxide (CO2) in flue gases. These analyzers are essential tools for Heating, Ventilation and Air Conditioning (HVAC) specialists, boiler technicians, and plumbers who perform combustion analysis on appliances such as boilers, heaters, ovens, pool heaters, and furnaces. By providing accurate measurements of gas levels, combustion analyzers offer valuable insights into the safety and efficiency of appliance operation. Also known as flue gas analyzers, these detectors typically consist of an analyzer unit, a pump to draw gas samples, sensors to measure gas concentrations, a sample probe to collect flue gases, and filters to protect the sensors from particulates. The data obtained from combustion analysis helps professionals optimize appliance performance, reduce emissions, and ensure a safe environment for building occupants.

Pros |

Cons |

|

✅ Combustion analysis helps reduce pollution into the atmosphere, ensures efficient operation, and reduces the risk of poisonous emissions entering indoor spaces. ✅ Detects carbon monoxide (CO), oxygen (O2), and carbon dioxide (CO2). ✅ Many models and features are now available for less than $500. |

⛔ Maintenance and calibration can be forgotten by users. ⛔ Sensors typically last from 24 to 36 months. ⛔ Some models do not detect all hazardous gases. ⛔ Some models may be tricky to use. |

Best Residential Combustion Analyzer?

We have tested the six top Combustion Analyzers for residential applications and are all priced under $800. These are our top six picks:

- Forensics Detectors, Professional Combustion Analyzer

- Testo 310 Residential Combustion Analyzer

- Forensics Detectors, Basic Combustion Analyzer

- Bacharach, Fyrite Intech Combustion Analyzer

- Forensics Detectors, Residential Combustion Analyzer

- Fieldpiece, Combustion Checker SOX

..some others:

- UEI Test Instruments Combustion Analyzers

- Wohler 450 Combustion Analyzer

- Inficon Combustion Analyzer

What Is a Combustion Analyzer?

A combustion analyzer detects gases such as carbon monoxide (CO), oxygen (O2), and carbon dioxide (CO2). Heating, Ventilation and Air Conditioning (HVAC) specialists, boiler technicians, and plumbers use these devices.

A combustion analysis is commonly performed on appliances such as boilers, heaters, ovens, pool heaters, and furnaces. Test results provide gas levels and insight into safe and efficient appliance operation. Based on these readings, adjustments may be needed to improve combustion efficiency and reduce carbon monoxide levels.

What Does a Combustion Analyzer Detect?

A combustion analyzer detects various gas concentration levels. Mostly they detector CO, O2 and CO2 gases, and various models have a variety of sensors such as:

• Oxygen (O2)

• Carbon monoxide (CO)

• Carbon dioxide (CO2)

• Exhaust gas temperature

• Intake combustion air temperature

• Draft

• Nitric oxide (NO)

• Nitrogen dioxide (NO2)

• Sulfur dioxide (SO2)

What Is the Purpose of Combustion Analysis?

There are two main purposes why combustion analysis is important and often used. This includes:

Emission Requirements

- When combustion takes place (like in your home furnace), there are emitted by-products such as carbon monoxide, sulfur dioxide, nitrogen oxides, and particulates (soot) that pollute the atmosphere. These toxic gases accumulate to produce acid rain and smog, contribute to long-term atmospheric damage, and cause short-term acute respiratory problems. To combat environmental harm, federal and state regulations govern the emission of these pollutants. Combustion analysis is performed to ensure gas emissions are within their thresholds. Adjusting the appliance, air-fuel ratio, or changing out deteriorated parts can help reduce pollution and meet regulations.

Improving Safety

- Ensuring that combustion appliances are working properly is an important safety consideration. Tune-ups on combustion appliances are required as the combustion process variables may drift with time. Slight changes can have a dramatic increase in toxic carbon monoxide. Effects such as backdrafting and spillage can result in toxic gases building up and releasing indoors. In addition, if the appliances are not operating within specifications, components may deteriorate and result in heater exchange cracking and pin-holes.

What Are the Different Types of Combustion Analyzers?

Residential Combustion AnalyzersThese are the most popular models that incorporate CO and / or O2 sensors. The user can perform a basic combustion analysis for residential appliances for less than $600. The Forensics Detectors Professional Combustion Analyzer is pictured below.

|

Commercial Combustion AnalyzersThese are built to detect a plethora of combustion flue gas metrics. This includes concentrations of gases such as O2, CO, CO2, NO, NO2, NOx, and SO2. Other important metrics such as draft, intake air temperature, flue gas temperature, and combustion efficiency are also shown. These units usually retail for over $1,000. |

Exhaust Gas Combustion Analyzers (Combustion Engines)These analyzers determine the gas concentrations emitted from a combustion engine found in a automobile, forklift, diesel engine, etc... (one can argue this should not be listed here, but you would be surprised how many folks believe a flue gas analyzer is good for a engine exhaust gas analysis). Non-dispersive infrared sensors are used, as required by the EPA measurement method. Gases measured include CO, CO2, hydrocarbon (HC), NO, NO2, and sometimes SO2. These analyzers are expensive and retail for over $4000. Note that these units use special filters, water traps and probes made specifically for internal combustion engine exhaust.

|

Continuous Emission Monitors (CEMs)These units are more advanced instruments designed to be fixed to an exhaust flue and continuously monitor the gas components (including smoke and particulate). CEMs are also used for feedback loop control, where the system can control input parameters to optimize combustion on the fly. They are found in large industrial facilities  |

How Do Combustion Analyzers Work?

A combustion analyzer is composed of electronics, a pump, and gas sensors. Below are the main components of these devices:

- Gas sample probe: A probe is used to extract gas from the flue.

- Pump: A micro-pump produces suction to draw gas from the flue stream and into the combustion analyzer via the probe.

- Filter assembly: The gas passes a water trap and filters. The gas sample is "conditioned" to ensure it arrives in a "prepared" and acceptable fashion to the sensors.

- Sensor chamber: The sensors are usually housed in a miniature chamber that delivers the gas to the sensor head.

- Gas sensors: The gas sensors convert the detected gas concentration to an electronic signal for analysis by the on-board microprocessor.

- Electronics & microprocessor: The processor then outputs the reading to the display. The processor performs computations to calculate relevant units such as COAF, EA, combustion efficiency, etc..

The most important components within the combustion analyzer are the gas sensors. These sensors rely on two primary gas sensor technologies. Low-cost units exclusively use electrochemical sensors. For the high-end units, combustion analyzers employ NDIR technology.

Sensor |

Working Principle |

Pros |

Cons |

|

Electrochemical Cell Sensors

|

The gas reacts with a working electrode, triggering an electrochemical redox reaction. A current is generated proportional to gas levels. Detection: CO, NO2, NO, O2, SO2 |

|

|

|

|

The infrared light is emitted and then absorbed by gas molecules. This absorption is detected with a photodetector. Using the Beer-Lambert law, the IR absorption and gas concentration are determined. Detection: CO, NO2, NO, SO2, HC, CO2 |

|

|

What Are Good Combustion Analyzer Levels When Testing Carbon Monoxide?

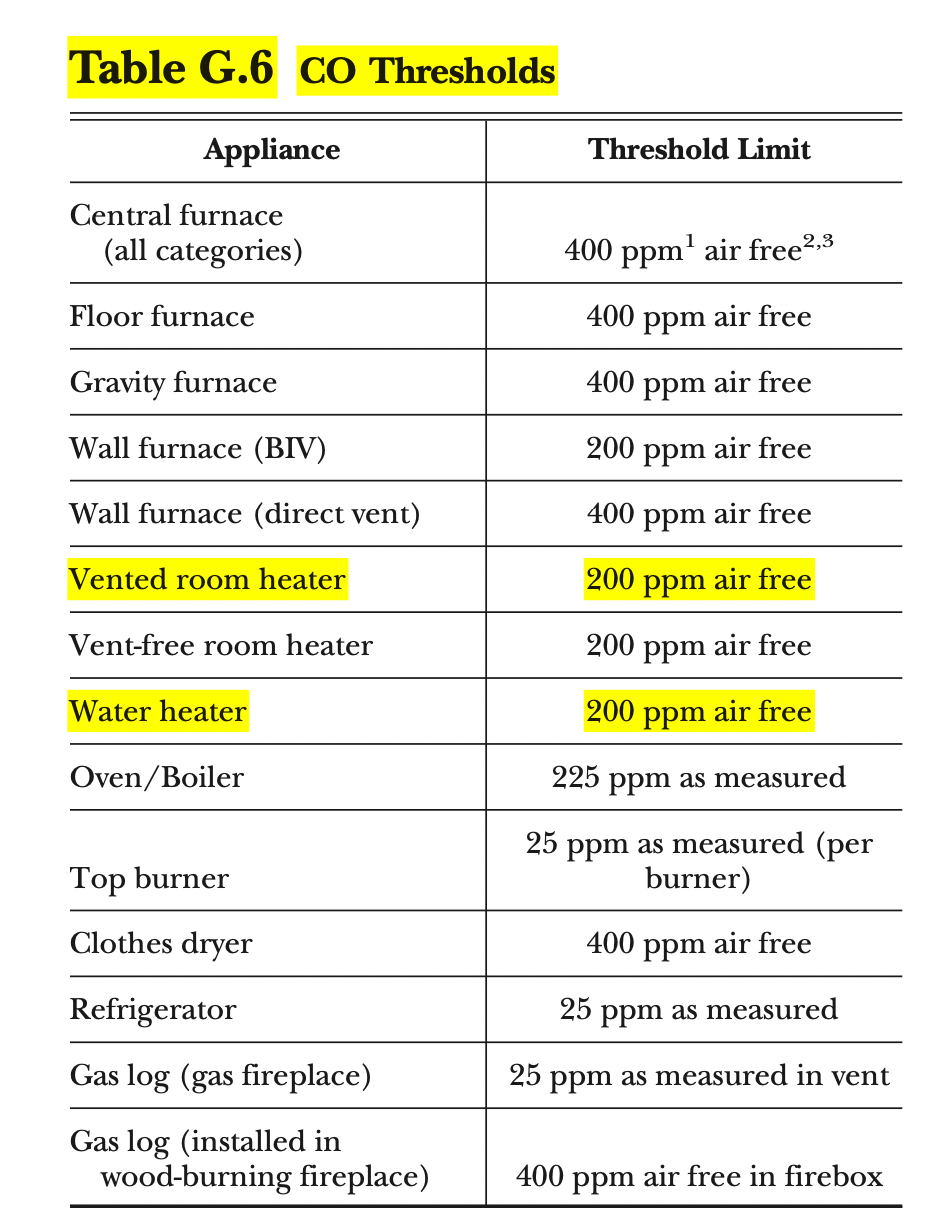

Various government agencies have recommended gas emission thresholds. Below are some examples. Please note that different thresholds are assigned depending on the appliance.

1. Building Performance Institute, ANSI/BPI-1200-S-2015 Standard Practice for Basic Analysis of Building

2. National Fuel Gas Code, ANSI Z223.1/NFPA 54.

This standard provides minimum safety requirements for the design and installation of fuel gas piping systems in homes and other buildings.

3. American National Standard/ CSA Standard for Vented Gas Fireplace Heaters, ANSI Z21.88-2009 & CSA 2.33-2009

What Are Good Combustion Analyzer Levels When Testing Oxygen?

The optimum fuel-air ratio results in the oxygen level being reduced from 21% (fresh air) to between 2-10% by volume after combustion. This value depends on the appliance, so check your user manual to see the recommended oxygen level for your specific appliance.

Do Combustion Analyzers Indicate Which Gas Is Being Detected?

Yes, they do.

Since there is a gas sensor array ranging from 1 to 4 sensors, the analyzer presents the corresponding gas levels. Sometimes detectors may calculate the gas value instead of directly measuring it. For example, by measuring oxygen, a combustion analyzer may "infer" the CO2 levels. Check to make sure which units are actually being "measured" and which are being "calculated."

What shall I Look out for when Purchasing a Combustion Analyzer for Residential use?

- A basic residential combustion analyzer typically comes with a pump, probe, and analyzer that includes O2 and CO sensors. Forensics Detectors has developed this unit for HVAC professionals, contractors, and maintenance engineers for residential boilers, heaters, or furnaces.

- The display screen shows CO, O2, COAF (CO air-free), and EA (Excess Air %). The detector can also be used as an ambient detector for general air quality measurements or plugged into the hand pump to function as spot detector.

- Note, this analyzer does NOT detect flue temperature nor calculate combustion efficiency. If that is necessary, we recommend the Bacharach or Testo versions.

- The product comes with an aluminum hard case, analyzer containing CO and O2 sensors with strong niobium magnets for mounting on appliances, electronic pump with stainless probe, hose assembly with three feet of high-temperature silicone tubing, water trap, particle and NOx filters with sensor cap, screw to mount sensor cap to the analyzer, USB charging cable, USB charger, calibration certificate, and clear English manual & instructions.

What Is a Combustion Analyzer Used For?

Combustion analyzers are typically used by HVAC specialists, boiler technicians, and plumbers to test flue gases and ambient environments. A combustion analysis is commonly performed on appliances such as boilers, heaters, ovens, pool heaters, and furnaces. Test results provide gas levels and insight into safe and efficient appliance operation. Some applications are highlighted below:

- Carbon monoxide emissions: Large amounts of carbon monoxide with the flue gas is not desirable, indicating poor combustion. It is also dangerous for the environment and occupants. In cases with spillage, backdraft, or a cracked heat exchanger, CO may poison occupants.

- Combustion efficiency: A combustion analyzer will calculate combustion efficiency. To improve performance, the technician may need to tune the air-fuel ratio or change out deteriorated parts. Also note that cost is a significant factor here in terms of reduced efficiency and losing heat per unit dollar.

- Safety, spillage, leakage, or cracked heat exchanger: A combustion analyzer can be used as an ambient point sampler to detect any spillage, backdraft, or a cracked heat exchanger.

Can a Combustion Analyzer Be Used to Detect a Cracked Heat Exchanger?

Yes indeed.

Combustion analyzers are often used to test register outlets, air ducting, and around the appliance to check for low levels of carbon monoxide. Low carbon monoxide in the ducting is a tell-tale sign of a cracked or pin-hole infested heat exchanger.

For suspected gas leaks in a pipe, joint, or appliance, we do not recommend using a combustion analyzer for pin-pointing gas leaks. A gas leak detector with gooseneck, semiconducting metal oxide sensor, and ppm reading is the most desirable detector for that specific application. See here.

How Do I Select a Combustion Analyzer?

To select the best combustion analyzer that serves your purpose, follow this guide. To narrow down your selection, start by thinking about these questions:

-

Am I using it for commercial or residential applications?

For residential situations, a combustion analyzer that has CO and O2 measured gas sensors will suffice and be more reasonably priced. Commercial applications require detection of more gases and a more expensive detector. Metrics include concentration of NO, NO2, SO2, and CO2, combustion efficiency, and others.

-

Which gases would I like to measure?

Depending on the specific gases you wish to measure, this will narrow the combustion analyzer selection very fast.

-

Do I need to detect flue temperature or combustion efficiency?

If combustion efficiency must be measured, then the probe needs a thermocouple. This capability raises the complexity and price of the combustion analyzer.

-

What is my budget and operating cost budget?

Combustion analyzers dramatically vary in cost. If you plan to use it daily, quality, after sales-service, calibration, and part replacement costs must be taken into consideration. Combustion analyzers have many components that can fail, including the pump, sensors, and probe assemblies.

-

Do I need advanced functions such as data-logging, bluetooth, or printing?

With the popularity of mobile phones, many technicians choose not to purchase printers with their analyzers. At one point, this was very common. Today, most service technicians are paperless and email customers photos of their appliance in action and the combustion analyzer data screen. Doing so allows for easy digital filing. Other features, such as data logging and Bluetooth communication, are available for the professional user.

-

Do I need specific accreditations with the monitor such as a NIST traceability calibration certificate?

Yes, you do. An important aspect of combustion analysis is accuracy, wich is a function of calibration. Ensure the NIST traceability calibration is performed in the USA and that your analyzer comes with a certificate signed by an engineer.

-

Do I require features such as a magnet for easy appliance mounting?

Magnet backs are becoming very convenient. Simply pop the unit on the metal appliance and it will hold. This frees one hand and makes combustion testing much easier.

-

Do I need sales support, USA location, or calibration service?

Some of the brands listed previously are not based in the USA. Be sure that you have technical help in the USA so you can easily pick up the phone and have support within minutes.

How Long Do Combustion Analyzer Sensors Last?

Residential combustion analyzers typically employ electrochemical cell technology sensors, which are used to detect O2 and CO. They usually last between 24 and 36 months. Check your user manual; sometimes it may be shorter.

How Do I Test My Combustion Analyzer? (Bump Testing)

The best way to test your combustion analyzer is to expose it to a known gas source. Generally referred to as bump testing, this is a good practice to perform regularly.

What Is Combustion Analyzer Gas Calibration?

Combustion analyzer calibration is the technical task of adjusting the detector to a more accurate gas readings. Gas sensors drift and degrade over time. Calibrate every 6 to 12 months.

How Do I Use a Combustion Analyzer?

The basic steps of using a combustion analyzer are as follows:

- Drill a hole in your flue. Follow appliance instructions or regulation instructions on where to take the sample measurement. It is different for different appliances, so double-check.

- Check your combustion analyzer and make sure it is calibrated. Ensure there is no water is in the water trap. Finally, check that you have the gas sample probe, tubing, filters, and that the battery is charged.

- Check the probe, tubing, and filters. Make sure it is connected with no vacuum leaks.

- Turn the analyzer ON.

- Turn ON the appliance that will be tested. Make sure it operating for at least 5 minutes.

- Connect the probe, tubing, and filter assembly to the probe. Take a fresh air reading: CO should read 0%, O2 should read 20.9%, and CO2 should read about 400ppm. If required, bump test the unit to confirm proper operation.

- Once normal readings are confirmed, begin taking your combustion flue gas measurement.

- Insert the probe in the flue hole and let the analyzer do its job. It will draw a gas sample and analyze the gas concentration.

- When placing the probe in the exhaust flue, ensure it remains in the hot exhaust for no longer than 2 minutes. Avoid high temperatures for prolonged periods (> 3 minutes) - this is especially important for commercial appliances where the flue gases are at extreme temperatures.

- Readings will usually stabilize after 60 seconds. Take a photograph of the analyzer display for your customer or record-keeping purposes.

- Ensure tubing and other items are clean before storing to avoid any contamination, residual odors, or toxic gases that may poison the sensor.

Some important tips to consider:

- Combustion analyzer user manual: Obviously, be smart and read your product manual. The above instruction list is generic and does not apply to every combustion analyzer.

- Appliance user manual: Read the appliance manual. If you are testing a forced air furnace, make sure to read the manual because there may be recommended oxygen levels to target in the flue gas.

- Code: Be privy to any rules and regulations in the city, state, or country that may be applicable.

- NFGC 54: The National Fuel Gas Code (NFGC 54) - Annex G Recommended Procedure for Safety Inspection of an Existing Appliance Installation highlights steps to perform a combustion carbon monoxide test. Some key elements include the following:

- The inspection procedures outlines the measurement of carbon monoxide (CO) - among others.

- Prior to inspection, ensure detectors are calibrated or tested in accordance with the manufacturer’s instructions.

- In addition, it is recommended that CO detectors have the following minimum specifications:

- Digital display for measuring ambient room and appliance emissions from 0 to 1,000 ppm in 1 ppm increments,

- Capable of converting CO measurements to air-free levels in ppm.

- Turn ON the forced air furnace (example).

- Measure the CO in the vent after 5 minutes of main burner operation.

- The CO should not exceed 200 ppm COAF

What to Look Out for When Performing a Combustion Analysis? (Extra Tips)

-

Ensure the analyzer is stored well within specifications.

-

When using the analyzer, condensation may occur and the water trap will slowly fill with water. Keep track of this and empty as necessary. Always empty the water trap before storing the unit.

-

The CO and O2 sensors typically have a life of 2 years. If taken care of, they can last longer (up to 3 years) but require more frequent calibration.

-

Ensure periodic calibration every 6 months so the performance of the detector remains within specification.

-

Follow best practices when selecting a combustion gas sample location for analyzing appliances. Follow local codes and appliance manufacturer instructions (i.e., NFGC, ANSI, BPI).

What Is the Difference Between ppm and %?

A typical combustion analyzer presents oxygen readings in % and carbon monoxide in ppm.

The typical scale of concentration for any gas is %vol. The means what % of the air volume is taken up by the gas in a volumetric measure. There are other measures based on weight and mols, but gas detection primarily involves readings on a volumetric basis.

The parts per million (ppm) scale has a direct conversion from %. 10,000 ppm = 1%. Both of these values are interchangeable. Once ppm values enter the 1000s, it is customary to start using %vol, as it is easier to say 1.1% vol than 11,000 ppm.

Conversion Example

Oxygen % value = (oxygen ppm / 1,000,000) x 100%

For example, if we have 5,000 ppm of oxygen, then we obtain:

Oxygen % value = (5,000 / 1,000,000) x 100%

Oxygen % value = 0.5%

Quick Conversion from ppm to %vol

100 ppm = 0.01%

1,000 ppm = 0.1%

10,000 ppm =1%

100,000 ppm =10%

1,000,000 ppm =100%

What Is the Difference Between CO and COAF?

Carbon monoxide is measured directly in most combustion analyzers, typically referred to as the "as-measured" CO level. This is the raw carbon monoxide level measured within the flue gas. It is presented on the combustion analyzer display screen as CO.

The carbon monoxide air free value is typically presented on your analyzer as COAF. This is the calculated, undiluted CO concentration obtained in flue gas, an ambient environment, or a gas environment where dilutive excess air exists.

Excess air dilutes the as-measured CO concentration. As such, the CO value is compensated (increased) to derive the absolute, undiluted CO concentration (corresponding to zero O2).

COAF is otherwise known as CO source concentration or CO source emission.

COAF is calculated using the following:

COAF = (COmeasured x 20.9) / (20.9 - 02measured)

As you can see, combustion analyzers must also measure O2 to be able to calculate COAF.

What Is Excess Air in Combustion?

Excess air (EA) is the additional air in a flue stream beyond what's required for complete combustion. The excess air dilutes the exhaust flue gases. Complete combustion occurs when zero oxygen is present in the flue gas. When there is a non-zero oxygen reading, this means excess air exists. Therefore, measuring oxygen is very important to determine EA and COAF. A common equation used to determine the excess air is shown below:

EA% = [[20.9/ (20.9 - 02measured)] – 1] x 100

What Is a Draft Measurement?

Some combustion analyzers can measure the draft, or flue gas speed, in the stack or chimney. If the velocity is too high, the boiler efficiency drops because the unit cannot transfer heat from the flame to the boiler. If the draft is too low, it could damage the boiler and burner or spill exhaust gases into the room.

Does a Combustion Analyzer Detect Hydrocarbon and VOCs?

No, it does not.

During incomplete combustion, hydrocarbons (HCs) and volatile organic compounds (VOCs) may be present in the flue gas due to incomplete combustion.

Can You Smell Combustion?

Yes, combustion typically produces detectable odors through the release of various gases and particles. The specific smell varies depending on the material being burned and combustion conditions.

Does a Combustion Analyzer Detect Soot?

No, it does not.

Professional models may have an option for detecting hydrocarbons or VOCs. Soot is particulate matter that makes up smoke, commonly seen emitted from diesel trucks. Although it is not always visible, a small amount of soot may still be present. An excessive amount of soot is not good as it means:

- Poor combustion efficiency

- Faster degradation of parts

- Poor internal heat transfer, preventing good thermal conductivity

- Eventual damage to the heat exchanger

Most Affordable Professional Combustion Analyzer?

The best and most affordable professional combustion analyzer is the Forensics Detectors Professional Combustion Analyzer with built-in pump and high-quality gas sample probe. This device is a workhorse for HVAC, contractors, plumbers, engineers, and technicians for combustion analysis of boilers, heaters, furnaces, and other natural gas or propane burning appliances. It is also perfect for indoor air quality, CO, and O2 gas analysis.

The unit is packed with advanced features such as a 32-bit microprocessor, color screen, real-time graphing, and data-logging functions. The large display shows CO, O2, COAF, and EA. The detector can also be used as (1) an ambient detector for general air quality measurements, (2) a spot detector, or (3) a combustion and flue gas analyzer.

The package includes a robust ABS waterproof hard case, model 600 analyzer with CO and O2 sensors, strong niobium magnet for easy mount, supreme point sample probe, hose assembly with three feet of high temperature silicone tubing, water trap, particle and NOx filters, USB charging cable, USB charger, USA NIST traceable calibration certificate, and simple English user manual.

Final Words

A combustion analyzer is a sophisticated gas detection device that requires more user involvement and maintenance compared to simple handheld gas detectors. With more moving parts and complex functionality, it is crucial to thoroughly read the user manual before operating a combustion analyzer to ensure proper usage and accurate results. Proper calibration is another critical aspect of combustion analyzer operation; the device should be calibrated with NIST traceable gas sources every 2 to 3 months for optimal accuracy. The cost of combustion and flue gas analyzers varies significantly depending on their features and intended application. For residential appliance testing, an analyzer that detects both carbon monoxide (CO) and oxygen (O2) can be purchased for less than $500. However, investing in a high-quality, well-maintained combustion analyzer is essential for HVAC specialists, boiler technicians, and plumbers to ensure the safety and efficiency of the appliances they service.

About The AuthorDr. Koz is the President of FORENSICS DETECTORS, where the company operates from the scenic Palos Verdes Peninsula in Los Angeles, California. He is a subject matter expert on gas sensor technology, gas detectors, gas meters, and gas analyzers. He has been designing, building, manufacturing, and testing toxic gas detection systems for over 20 years.

Every day is a blessing for Dr. Koz. He loves to help customers solve their unique problems. Dr. Koz also loves spending time with his wife and his three children going to the beach, grilling burgers, and enjoying the outdoors. Read more about Forensics Detectors here. Email: drkoz@forensicsdetectors.com |