Oxygen analyzers for welding are essential gas detection devices used to ensure an inert environment for optimal welding results. These analyzers continuously monitor the welding atmosphere, confirming that oxygen levels remain below 100 ppm, which is crucial for preventing oxidation and maintaining weld quality. A typical O2 analyzer consists of a probe to sample the gas, a pump to draw the sample, an oxygen sensor to measure the O2 concentration, and a display to present the readings. In recent years, the price of oxygen analyzers designed for welding applications has decreased significantly, with reliable units now available for less than $500. By utilizing these affordable and efficient gas detection tools, welders can guarantee the integrity of their work, minimize defects, and enhance the overall quality of their welded products.

Pros |

Cons |

|

✅ O2 analyzer prices have dropped as low as $500. ✅ Reducing oxygen improves weld joints. ✅ Simple, fast, and small units. |

⛔ Oxygen becomes dangerous to life when displaced to less than 19.5%. Care must always be taken to prevent low levels of O2. ⛔ Oxygen analyzers can get very expensive. ⛔ Electrochemical oxygen sensors have a limited life from 2 to 3 years. |

Best Oxygen Analyzer for Welding?

There are many oxygen analyzers for welding on the market. The reputable brands include the following:

- Forensics Detectors Oxygen Analyzer for Welding

- Pipe Purge Masters Weld Purge Monitor

- Argweld Weld Purge Monitor

- Tec Pen Weld Purge Monitor

- Argo-Naught Oxygen Analyzer for Welding

- Pipe Tools Oxy Pro

- Aquasol Oxygen Monitor for Welding

- AII GPR-1000 WP Pipe Weld Purge PPM Oxygen Analyzer

- AMI Oxygen Analyzers for Welding

- Orbitec Oxygen Analyzers for Welding

- Alpha Omega Instrument Trace Oxygen Analyzers

Why Is Reduced Oxygen So Important for Welding?

While welding, the objective is to remove as much oxygen as possible. The best welding results occur when there is no oxidation, hence the need for minimal oxygen levels. Since O2 naturally exists in the air at 20.9%, it is difficult to eliminate oxygen in small spaces.

Weld oxidation degrades the mechanical properties of a pipe and reduces its resistance to corrosion. To reduce this oxidation, the oxygen content must be dramatically lowered.

For welding, inert gases are used to displace and remove the oxygen. This is where confidence in accurate O2 detection is important. An oxygen analyzer for welding does exactly that. It reliably confirms the exact oxygen level while welding.

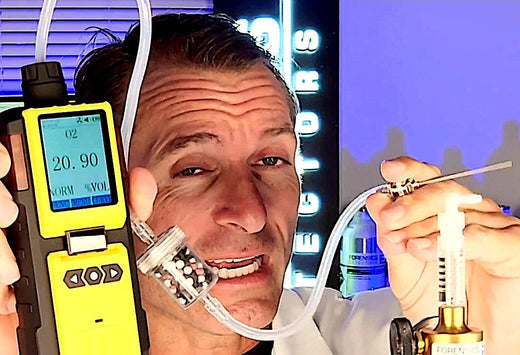

Example: Testing Weld Analyzer to 100% Argon Gas

Benefits of Using an Oxygen Purge Analyzer?

The most important benefit of using an oxygen purge analyzer is to ensure that O2 levels remain low. This reduces oxidation and oxide thickness while welding.

Many academic studies show the relationship of welding oxygen content and resulting oxide thickness (oxidation). For example:

- One study shows an oxide thickness of about 0.7 μm with oxygen at 30 ppm compared to about 1.5 μm with oxygen at 280 ppm.

- Oxidation was responsible for the cracked specimens welded under high oxygen content.

- This results in decreasing corrosion resistance of the welding samples.

These studies show the importance of sensitive oxygen detection down to 100 ppm while welding.

The image below visually shows the correlation between oxygen content and oxidization. The darker the weld, the more oxidization. See more here.

- Reduced time as there is no need to depend on time for purge estimates.

- Reduced gas consumption when purging. It is also easier to control the amount required.

- Ensured quality as welding can begin when oxygen depletion is complete, so no need to worry about welding too early.

What Does an Oxygen Analyzer for Welding Do?

Oxygen analyzers are sometimes called:

- Inert shielding gas monitors

- Weld purge monitors

- Oxygen analyzers for welding

- Trace oxygen analyzers

- Oxygen purge monitors

They all refer to measuring instruments that detect oxygen and provide a quantitative measurement of the O2 levels for welding applications.

An oxygen analyzer tracks the O2 concentration and displays results in % or parts per million (ppm).

For welding, O2 analyzers also present the user with a % or ppm concentration.

Does the TIG Electromagnetic Emissions Interfere with the Oxygen Analyzers?

The welding process such as TIG, switches high current and voltage that produces a large dose of electromagnetic interference (EMI) and radiation that interferes with electronics, including the oxygen analyzer itself. Ensure you have a welding oxygen analyzer that has been designed to take this extra EMI into consideration in its design, like the Forensics Detectors that does not have this problem.

How Is Oxygen Gas Detected?

Oxygen is detected using an O2 sensor. Within the oxygen analyzer, a specific sensor measures the oxygen molecules. The reaction produces an electronic signal that represents the O2 concentration. A small electrochemical oxygen sensor is shown below.

How Does an Oxygen Analyzer Work?

An oxygen analyzer for welding works by using a specialized sensor cell to detect O2 concentrations. For electrochemical sensors, the oxygen gas reacts with a working electrode and triggers an electrochemical redox reaction. A current is generated proportional to oxygen levels that is converted to a quantitative concentration (related via a calibration curve). For more extensive information, see here.

What Is the Difference Between Electrochemical and Zirconia Oxygen Sensors?

O2 Sensor Technology |

Working Principle |

Pros |

Cons |

|

Electrochemical Cells (100 ppm) |

|

|

|

|

Zirconia Sensors (< 100 ppm) |

Zirconia allows oxygen ions to travel, generating an electrochemical voltage when exposed to gases at different concentrations. |

|

|

What Are Safe Oxygen Levels?

What Are Safe Oxygen Levels?

When welding, low oxygen levels are desired in the confined workspace, such as a tube or gas chamber. With that being said, it is important to know that inert gas leaks and depleted O2 levels in your breathing environment can be dangerous.

Various government agencies have recommended oxygen gas limits. Some examples are shown in the table below.

Agency |

Recommendation / Requirement |

|

|

Air is considered oxygen-deficient below 19.5% |

| National Institute for Occupational Safety and Health (NIOSH) |

Air is considered oxygen-deficient below 19.5% |

|

American Conference of Governmental Industrial Hygienists (ACGIH)

|

<18% is minimum partial pressure without the need for respiratory protection at normal atmospheric pressure

|

How Can I Test My Oxygen Analyzer?

The best way to test your oxygen detector is to expose it to an inert gas, such as argon or nitrogen. Since air has 20.9% O2, bump testing it to pure nitrogen or reduced oxygen levels is a good check.

What Will Happen If I Breathe into My Oxygen Analyzer?

If you breathe onto your oxygen analyzer, the O2 reading will quickly decrease as breath exhalation has depleted oxygen levels of about 17%.

How Do I Choose an Oxygen Analyzer for Welding?

To select the best oxygen analyzer for welding, make sure to ask these questions:

- Does the oxygen analyzer have a pump? Avoid using handheld aspirators because they create variable pressure (pulses) and affect sensor readings. Continuous, electronic micro pumps are much more desirable in an analyzer.

- How low do you need to detect O2? Depending on your weld application and the metals being used, 100 ppm may suffice. In this case, an oxygen analyzer with 0.01% (100 ppm) resolution and electrochemical sensors will work fine. If your welding application requires very low O2 levels (down to 10 ppm or even 1 ppm), you will need a 1 ppm oxygen analyzer. For these extremely low concentration readings, you will need an analyzer with zirconia sensors.

- What accessories do I need? Typically, an oxygen analyzer comes with tubing, filters, carry case, and stainless steel probes.

- Budget? Oxygen analyzers for welding range from $500 to $5000. Typically, electrochemical sensors sensitive to 100 ppm can be purchased for less than $500. Zirconia based sensors (1 ppm) are sold for over $3000.

- Calibration certificate? Ensure the unit is calibrated with National Institute of Standards and Technology (NIST) traceable sources to ensure the highest level of accuracy. Ensure the calibration certificate mentions calibration location, standard, and all technical details, including calibration date.

How Long Do Oxygen Analyzers Last?

O2 analyzers with electrochemical sensor cells last from 24 to 36 months. Zirconia oxygen sensors last much longer but are more expensive.

What Is Oxygen Analyzer Bump Testing?

- Bump testing is a procedure when one exposes the oxygen analyzer to a small amount of “blast” target gas to ensure the detector operates as expected.

- The function of this test is to verify proper operation and build user confidence, particularly in hazardous applications.

- It is recommended to bump test when first purchased, followed by weekly tests. This is especially important in LIFE-THREATENING and / or DANGEROUS applications to verify detector operation. See video explanation here.

- For oxygen analyzers, we recommend bump testing with pure argon or nitrogen gas.

How Do I Take Care of My Oxygen Analyzer?

- Store your oxygen analyzer at normal room temperature.

- Store it away from electromagnetic or magnetic sources, such as phones or electronic equipment.

- Store it in a clean environment with no dust or particles. If it comes with a case, use it for ensured protection.

- Store it away from any exhaust gas, concentrated vapors, or harsh chemicals that may poison the sensor.

- Store it in a stable place where there are no vibrations or continuous shaking.

How Do I Properly Use an Oxygen Analyzer?

When operating your oxygen analyzer for welding, there are some essential tips to consider. Be smart and start by reading your product manual.

Before starting, set up your weld purge system. This is typically an inert purge chamber (glove box) or a pipe purge system arrangement. There are other hardware setups that create a bubble of inert gas around the welding area.

- Ensure the oxygen analyzer has been bump tested and validated as operational.

- Turn ON and allow the analyzer at least 60 seconds to come to a stable reading (this may take longer for zirconia-based oxygen sensors).

- Check all tube connections via the filter and barbs. It is extremely important to ensure there are no vacuum leaks, which will introduce oxygen and elevate the readings.

- Place the probe at your sample location.

- Ensure the pump is running. You will soon see the O2 values decreasing once the inert gas starts to displace the oxygen.

- Make the necessary flow adjustments to your inert gas to prevent waste while maintaining low oxygen levels.

- Once finished, allow the analyzer to draw fresh air.

- Allow the analyzer to return to 20.90.

- Turn OFF and store the analyzer.

What Is the Difference Between ppm and % Oxygen?

The typical scale of concentration for oxygen is %. For low levels, less than 1%, the parts per million scale is used (ppm).

For welding, the ppm scale is more commonly used since we are most interested in low values to ensure an inert environment. Conversion between ppm and % is easy. Here is a quick oxygen concentration conversion:

10 ppm = 0.001%

100 ppm = 0.01%

1,000 ppm = 0.1%

TIG Welding

In TIG welding, monitoring oxygen levels is crucial due to the use of an inert shielding gas, typically argon, to protect the weld from air exposure. High oxygen levels can react with the shielding gas, leading to weld defects like porosity or oxidation. Thus, employing an oxygen monitor is essential in TIG welding to maintain safe oxygen levels. This device warns the welder if oxygen levels rise too high, prompting actions like adjusting gas flow or enhancing ventilation. This practice is key to ensuring weld quality and integrity, minimizing defects and enhancing the final product's quality.

How often should I test or calibrate my Oxygen Leak Detector?

It is best to bump test before using the Oxygen leak detector. Calibration should be performed every 6 to 12 months. Calibration can be done by the Forensics Detectors lab or can be performed by the customer following our calibration tutorials. Items required are:

Calibration T-piece & Tubing

Calibration Gas (N2)

Calibration Gas Regulator (C10)

What is the Maintenance Schedule for my Oxygen Leak Detector?

For optimal performance and accuracy, we advise the following regimen for your oxygen monitor for welding

1. **Calibration**: Calibration should be done every 6 or 12 months. Calibrating to 20.9% in air before starting a weld is also recommended to increase accuracy and takes less than 10 seconds.

2. **Replacement Schedule**: Plan to replace sensors every 2 to 3 years.

Can You Smell Oxygen While Welding?

Pure oxygen itself is odorless. However, during welding, you may detect distinct odors from ionized air, ozone production, and metal vapors created by the welding process.

Final Words

Oxygen analyzers are essential gas detection devices for maintaining low oxygen levels in welding environments, as even small variations in O2 concentration can greatly impact weld quality. By continuously monitoring the welding atmosphere and ensuring oxygen levels remain below 100 ppm, these analyzers help minimize defects and costly rework. Investing in an oxygen analyzer ultimately saves time and money by reducing welding defects and increasing productivity. With affordable handheld and stationary models now available, featuring probes, pumps, sensors, and displays for accurate real-time measurements, welders can easily incorporate these crucial tools into their workflows to ensure consistent, high-quality welds.

About The AuthorDr. Koz is the President of FORENSICS DETECTORS where the company operates from the scenic Palos Verdes Peninsula in Los Angeles, California. He is a subject matter expert on gas sensor technology, gas detectors, gas meters, and gas analyzers. He has been designing, building, manufacturing, and testing toxic gas detection systems for over 20 years.

Every day is a blessing for Dr. Koz. He loves to help customers solve their unique problems. Dr. Koz also loves spending time with his wife and his three children going to the beach, grilling burgers, and enjoying the outdoors. Read more about Forensics Detectors here. Email: drkoz@forensicsdetectors.com |