A 5 gas exhaust gas analyzer is a device that measures the emissions from various engines, including those in forklifts, grinders, power tools, vintage cars, motorcycles, automobiles, and small gasoline engines like portable generators. Gas detection is crucial in these analyzers, with 5 Gas Analyzers being a popular choice for detecting the most important gas combination: carbon monoxide (CO), carbon dioxide (CO2), nitrogen oxides (NOx), oxygen (O2), and hydrocarbons (HC). By analyzing the exhaust gas composition, these devices provide valuable insights into engine performance, efficiency, and potential issues that may affect operation and cause toxic gas inhalation. Utilizing a small engine exhaust gas analyzer ensures proper functioning and safety through accurate gas detection.

Pros |

Cons |

|

✅ Affordable Exhaust Gas Analyzer for CO is now available ✅ Easy test to perform, takes less than 2 minutes ✅ Exhaust Gas Analyzers can help to identify gas polluting engines. ✅ A 5 gas analyzers measures exhaust emissions, analyzing levels of carbon monoxide (CO), carbon dioxide (CO2), nitrogen oxides (NOx), oxygen (O2), and hydrocarbons (HC) |

⛔ Exhaust Gas Analyzers are very expensive ⛔ People use regular CO meters for exhaust testing which is wrong, water trap and filters are needed ⛔ Carbon Monoxide is a toxic gas and using small engines and forklift vehicles indoors can kill people |

Best Exhaust 5 Gas Analyzer?

The most trusted and best five gas analyzer that reads emissions:

- Forensics Detectors - 5 Gas Analyzer

- Bridge Analyzers - Exhaust Gas (2 gas, 4 gas, or 5 gas)

- Nova Analytical Instruments - Portable Exhaust Gas Analyzer (6 gas)

- Ansed Diagnostic Solutions - Automotive Exhaust Gas Analyzer Kit (5 gas)

- InfraRed Industries - Vehicle Exhaust Gas Analyzer (5 gas)

- MRU Instruments - Exhaust Emission Analyzer (7 gas)

- Mustang Exhaust Gas Analyzer (5 gas)

What is an Exhaust 5 Gas Analyzer?

A 5-gas analyzer is an essential instrument in the field of automotive engineering, particularly for the analysis of exhaust emissions from internal combustion engines found in vehicles such as cars and trucks. This sophisticated device conducts precise measurements of five principal exhaust gases: carbon monoxide (CO), carbon dioxide (CO2), nitrogen oxides (NOx), oxygen (O2), and hydrocarbons (HC). These measurements are critical for assessing the engine's combustion process efficiency, optimizing the air-fuel ratio, and evaluating the engine's overall operational performance.

The analyzer plays a pivotal role in ensuring vehicles adhere to established emission standards and environmental regulations by detecting and quantifying excessive levels of pollutants. The data procured from this analysis is instrumental in pinpointing and rectifying engine malfunctions, thereby mitigating environmental pollution, and improving vehicle fuel efficiency and safety standards.

5 Gas Analyzer Uses

A 5 gas analyzer is used by automotive experts and combustion engine experts for the following uses:

-

Dynamic Road Testing: Real-time data acquisition during on-road vehicle operation, crucial for assessing performance in varying driving scenarios.

-

Fuel and Emission Diagnostics: Identifies inefficiencies and anomalies in fuel systems and emissions, crucial for maintaining engine health and meeting environmental standards.

-

Carburetor Balance Check: Ensures optimal carburetor calibration, critical for achieving peak engine efficiency and performance.

-

Catalytic Converter Evaluation: Gauges the efficiency of catalytic converters, a key aspect in reducing harmful emissions.

-

Leak Detection: Swiftly pinpoints vacuum and exhaust leaks, essential for preventing engine damage and maintaining efficiency.

-

Smog Analysis: Detects the presence of smog-causing emissions, helping vehicles comply with environmental regulations.

-

PCV System Inspection: Evaluates the performance of the PCV (Positive Crankcase Ventilation) system, key in controlling engine emissions.

-

RPM Measurement: Accurately measures RPMs in diverse engines, including 2-stroke, 4-stroke, and rotary, offering insights into engine speed and health.

-

Fuel Mixture Optimization: Aids in fine-tuning fuel injection and carburetor settings, enhancing fuel efficiency and engine performance.

Which Gas Sensors are in a 5 Gas Analyzer?

-

Electrochemical (CO) Carbon Monoxide Sensor: 0 - 20,000 ppm with 1 ppm resolution. This sensor provides highly accurate measurements of carbon monoxide levels, essential for detecting harmful exhaust emissions and ensuring vehicle safety.

-

Electrochemical (O2) Oxygen Sensor: 0 - 30.0 %vol with 0.1 %vol resolution. Offers precise monitoring of oxygen levels in the exhaust, crucial for evaluating combustion efficiency and optimizing fuel-to-air ratios.

-

Electrochemical (NO for NOx) Nitrogen Oxide Sensor: 0 - 5000 ppm with 1 ppm resolution. Capable of detecting even minute concentrations of nitrogen oxides, this sensor is key in assessing emissions compliance and identifying potential engine issues.

-

Non-dispersive Infra-Red (NDIR) Carbon Dioxide (CO2) Sensor: 0 - 20.0 %vol with 0.01 %vol resolution. Utilizes advanced NDIR technology to accurately measure CO2 levels, vital for monitoring combustion processes and environmental impact.

-

Non-dispersive Infra-Red (NDIR) Hydrocarbons (HC EX) Sensor: 0 - 10,000 ppm with 1 ppm resolution. This sensor efficiently quantifies hydrocarbon emissions, providing essential data for engine tuning and compliance with emission standards.

Cheapest Exhaust Gas Analyzers for Forklift, Vintage Cars, Motorcycle, Power Tools and Small Engines

It is often not required to have a 5 gas analyzer, since they are expensive and more complicated to operate. At times, a single carbon monoxide exhaust gas analyzer or NOX gas analyzer may be just fine for the emission analysis. In that case, a single CO or NOx exhaust gas analyzer can be purchased for less than $900. These single gas analyzers are perfect for Forklift, Motorcycle, Power Tools and Small Engines.

How Does an Exhaust Gas Analyzer work?

An exhaust gas analyzer works by:

- First drawing the exhaust gas from the engine exhaust tailpipe. This is accomplished via a stainless steel probe.

- The probe is attached to an alligator clip so that the user can mount the probe nicely onto the exhaust tip.

- High temperature silicone is used for the tubing material to deliver the gas through the components and into the gas analyzer.

- The gas experiences a rapid change in temperature and the dew point changes resulting in condensate (water). The water trap functions to trap the condensate water so it does not reach and damage the gas analyzer.

- The gas continues through the water trap and through the NOx filter which filters the acidic gas components such as NO2 and NO. NO2 and NO may create cross interference within the CO sensor that will severely hamper the accuracy of reported CO concentration.

- The gas then enters the gas analyzer at about room temperate. The gas is ready for gas sensor analysis. The analyzer presents the user with the detected gas concentration.

- The gas is then emitted from the analyzer output port and into the ambient environment.

How does an Exhaust Analyzer help to Diagnose Engine Problems?

An exhaust gas analyzer is used for the following reasons:

- Occupational Safety: By measuring the emissions produced by an engine, the carbon monoxide concentration can be determined, so excessive CO is not produced. This information can then be used to make any necessary repairs or adjustments so carbon monoxide does not inundate the indoor space and exceed 50ppm TWA (OSHA).

- Performance: By measuring the emissions produced by an engine, a small engine exhaust gas analyzer can help identify problems that may be affecting performance. For example, if the analyzer detects high levels of carbon monoxide or hydrocarbons, it may indicate a problem with the fuel mixture or ignition timing. By identifying and correcting these issues, the engine can run more efficiently and produce more power.

- Emission Regulations (CARB): Combustion engines are subject to emissions regulations, and using a small engine exhaust gas analyzer can help ensure that they are meeting these requirements. For example, small off road engines (SORE) are subject to carbon monoxide emissions in grams per kilowatt-hour as stipulated by CARB.

Exhaust Gas Analyzers

Engine exhaust gas analyzers come in different styles, each designed to meet specific needs. Here are the three main types:

Professional Exhaust Gas Analyzers (Large and Expensive)

These are used for official SMOG automotive exhaust gas analysis to measure the emissions from a vehicle's exhaust system. They are typically used in automotive repair shops and authorized smog inspection stations to ensure that vehicles meet emissions standards. These analyzers measure CO, CO2, O2, and NOx emissions. Companies like HORIBA, AMETEK Land, Advanced Energy, Hubei Cubic-Ruiyi Instrument Co., Ltd and NIRA manufacture these complicated professional exhaust gas analyzers used to qualify vehicle emissions.

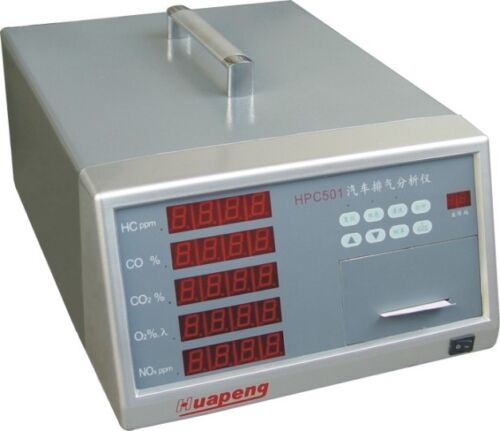

Portable Gas Analyzers (Medium Size and Cost)

Portable gas analyzers are designed to be carried to different locations and are often used by mechanics for check-up, safety diagnostic and tune-up, performance objectives. Used for small gasoline engines, motorcycles and forklifts. They are lightweight and compact with most often built in printing functions and typical analyze NOx, CO, HC, and O2 emissions.

Hand-Held Exhaust Gas Analysers (Cheapest)

Hand-held exhaust gas analyzers are similar to portable gas analyzers, but they are smaller and more compact. They are designed to be held in the hand and be battery operated. Most popular used with forklifts, motorcycles, small gasoline engines, portable generators, leaf blowers, lawn mowers, grinders, small engine power tools and portable generators. These analyzers can measure CO, CO2, HC, and O2 emissions and have a sensor life of several years.

Below is a nice example the Forensics Detectors Exhaust Gas Analyzer detecting Carbon Monoxide on a 2003 BMW Z4.

What is the Recommended Tool to Check Exhaust Gas Emissions?

Motorcycle Exhaust Gas Analysis

Motorcycles have smaller engines compared to cars, but also are culprits in carbon monoxide emissions. They are classified as "light duty". For motorcycles, carbon monoxide emissions are 12 g/km while Euro 5 standard calls for 1 g/km.

Portable Generators Exhaust Gas

Portable generators are commonly used in outdoor activities, such as camping, tailgating, and construction sites. Portable generators kill many victims every year due to misuse or underestimated carbon monoxide emissions.

Power Tools Exhaust Gas Analysis

Power tools, such as chainsaws, leaf blowers, and lawn mowers, are commonly used in landscaping and construction. Small engines are also used in mixers and other specialty construction equipment.

Below is an example of a small engine mixer that Dr. Koz measured to have carbon monoxide emission of over (0.4%) 4000ppm.

Forklift Exhaust Gas Analysis

Forklifts are commonly used in warehouses, construction sites, and manufacturing plants. Because they are used indoors, they should be regularly inspected for high carbon monoxide emissions. Federal OSHA regulations don't specify the allowable emissions in forklift engine exhaust, but California OSHA regulations limit emissions to 1.5 percent CO for the larger engines (above 140 cubic engines), with higher limits for smaller engines, see table below.

Maximum Allowable Standards for Internal Combustion Engine Exhaust Emissions.

|

|

|

|

|

2.3%vol (23,000ppm) |

|

|

|

|

|

|

Although in theory a properly tuned LPG-fueled engines such as forklifts should not emit any carbon monoxide gas, this is never the case simply because the engine and all components are not perfect, they degrade, change with time, conditions and hence, never a theoretically perfect combustion process.

Therefore, the only alternative, is to regularly check the CO emission levels and tune the engine for minimal CO emissions using a carbon monoxide exhaust gas analyzer.

At the ideal air-fuel ratio, the CO concentration in the exhaust gas of an LPG-fueled engine will be 0.4 percent (4,000 ppm). In a warehouse with limited ventilation and continuous use of the forklift, even this so called "industry acceptable CO level" may present deadly consequences.

OSHA CFR 1910 states CO exposure levels cannot exceed 50 Parts per Million (PPM) over a Time-Weighted Average (T.W.A.) for an 8-hour period. This level refers to the air within the indoor space, not the CO percentage coming out of the forklift’s tailpipe. If the warehouse or facility is small or doesn’t have sufficient air exchange for the number of operating lifts trucks, the 50ppm TWA level may be quickly exceeded. Hence the need for a low level CO detector within such facilities or a portable CO meter when operating the engines (which cost less than $100).

What is the Difference between a Combustion Analyzer and an Exhaust Gas Analyzer?

A combustion analyzer is made for home appliances such as heaters, boilers and ovens. Typically fueled by natural gas or propane. The carbon monoxide range in these analyzer are typically 0-1000ppm which is more than sufficient.

Exhaust Gas Analyzers are similar, but have a larger carbon monoxide detection range, typically 0-2% (0-20,000ppm). This because gasoline engines have the potential to emit high concentrations of carbon monoxide.

So the point is the following. Do not use a combustion analyzer to perform a gasoline engine exhaust gas measurement. You will most likely blow the CO sensor (known as sensor poisoning) in the combustion analyzer as gasoline exhaust CO gas emission on a cold start exceeds the maximum combustion analyzer CO limit, which is usually 1000ppm. In addition, do not use a exhaust gas analyzer to perform a combustion analysis. The fidelity of the exhaust gas analyzer's CO sensor resolution is 0.01% volume. The resolution is not fine enough to perform a useful combustion analysis. So pay attention to this subtly.

Other components such as water traps, NOx filters and gas sensors are similar.

Can A Vehicle's Exhaust Produce A Detectable Odor?

Vehicles may produce smelly exhaust fumes during testing, mostly due to unburnt hydrocarbons and aldehydes.

Final Words

Exhaust gas analyzers are essential for measuring engine emissions from various sources, including forklifts, motorcycles, small engines, vehicles, power tools, and generators. By detecting concentrations of gases such as CO, HC, O2, CO2, NO2, and NO, these analyzers provide crucial information about engine performance, efficiency, and potential issues. Gas detection is vital for ensuring engines run safely, meet emission regulations, and perform optimally. Different types of exhaust gas analyzers, such as automotive, portable, and hand-held models, cater to specific needs. The most popular type, the carbon monoxide analyzer, reports CO levels to ensure indoor environments remain below the OSHA limit of 50ppm.

About The AuthorDr. Kos Galatsis ("Dr.Koz") is the President of FORENSICS DETECTORS where the company operates from the scenic Palos Verdes Peninsula in Los Angeles, California. He is a subject matter expert on gas sensor technology, gas detectors, gas meters, and gas analyzers. He has been designing, building, manufacturing, and testing toxic gas detection systems for over 20 years.

Every day is a blessing for Dr. Koz. He loves to help customers solve their unique problems. Dr. Koz also loves spending time with his wife and his three children going to the beach, grilling burgers, and enjoying the outdoors. Read more about Forensics Detectors. Email: drkoz@forensicsdetectors.com |