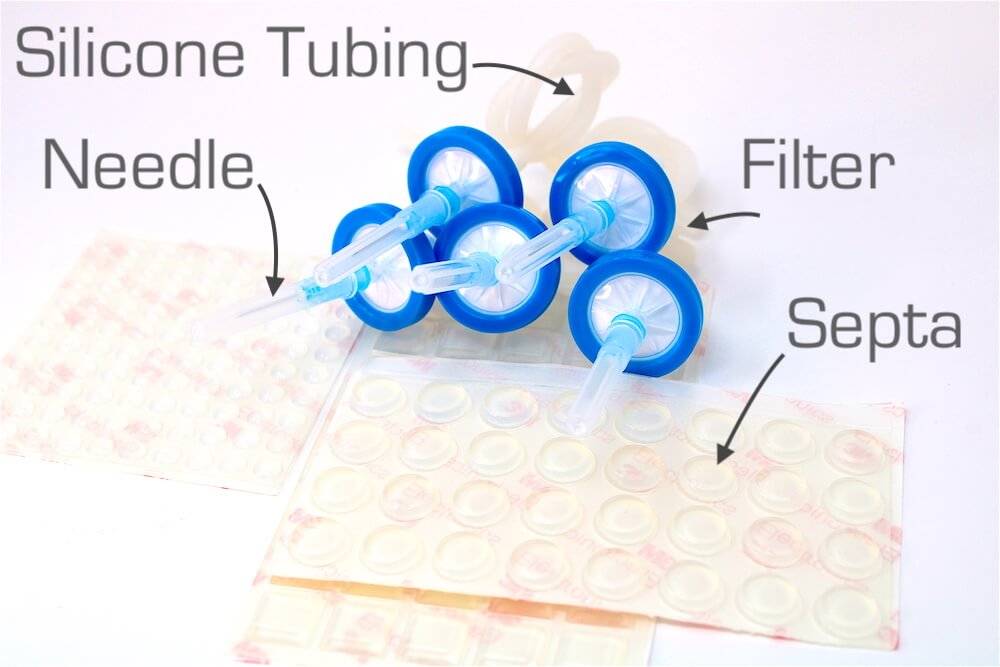

Introducing our professional CO2 Headspace MAP Analyzer, designed for accurate carbon dioxide measurement in modified atmosphere packaged (MAP) products. This portable, user-friendly device features a built-in pump and intuitive operation, allowing for quick and easy analysis. Simply insert the probe's needle tip through a septa seal pad into the food pack to begin. The color screen, large digits, and real-time graphing provide clear data visualization. Equipped with an advanced dual-channel NDIR CO2 sensor and a 32-bit microprocessor, this analyzer delivers reliable results in under 20 seconds. The included headspace kit, containing needles, filters, and septa, enables immediate MAP measurements.

Pros |

Cons |

|

✅ Quick and accurate CO2 measurement in food packaging (results in under 20 seconds) ✅ Portable and user-friendly with intuitive operation ✅ Essential for food safety, quality control, and extending shelf life. |

⛔ Relatively expensive (costs can reach thousands of dollars) ⛔ Requires destructive testing (puncturing the food packet) ⛔ Cannot detect other gases like carbon monoxide without additional features |

Dr. Koz developed a high-performance military spec CO2 NDIR sensor as part of a USA government NAVY seal project over 20 years ago!

Headspace Analyzer Models?

Depeding on your requirements, you may need to detect CO, CO2 and O2, or a combination of these gases in your food packaging. Our other headspace analyzers include:

Who Needs a CO2 Headspace Analyzer?

Modified atmosphere packaging headspace analyzers are used in the food packaging industry to ensure the quality and safety of food products.

Food: These analyzers measure the composition of gases in the headspace, or the air between the food and the packaging, to ensure that the environment inside the packaging is ideal for the food product.

Packaging: The analyzers are used by food manufacturers, processors, and distributors to extend the shelf life of their products, prevent spoilage, and maintain freshness.

Compliance: The analyzers are also used to comply with food safety regulations and ensure that the food products meet certain quality standards.

Preservation: Some common food products that require modified atmosphere packaging headspace analysis include meat, poultry, seafood, dairy products, and fruits and vegetables.

What are MAP Headspace Gas Benefits?

Headspace and Modified Atmosphere Packaging (MAP) are crucial for preserving various perishable items, including fresh produce, dairy products, seafood, and meat products. However, the MAP requirements vary depending on the type of food. Each food product has specific levels of oxygen and carbon dioxide concentration that must be maintained. To preserve the quality and freshness of the food, high levels of carbon dioxide are often used as an antimicrobial measure.

Market Size and MAP Benefits?

Many of the nutritional benefits of food are inexorably connected to freshness. Hence, the focus of packaging is evolving from simply extending shelf life to also preserving food quality. This becomes more important when food is not processed, but is sold fresh. Modified Atmosphere Packaging (MAP) can slow the processes that cause deterioration of food quality. Therefore, MAP sales are growing and reached $6.4 billion in 2020. Sales are expected to grow even higher in the 2021-2027 period.

How to Perform a Headspace Analysis?

- Ensure you have a properly working and calibrated headspace analyzer.

- Ensure the pump is ON and drawing air.

- Place a septa on the packaging you wish to test. Septas are important as they will prevent external atmospheric air from entering the packaging that may distort test results.

- For CO2, ensure the CO2 is reading between 0.1 down to 0.04% in normal air. Clean fresh outdoor air has 0.04% (400ppm), so that means the CO2 reading on the analyzer should be between 0.04 to about 0.1% to be in good shape.

- If all is OK up to this point, then you are ready to insert your needle through the septa and into the packaging. Be slow and careful.

- Once the needle is in the package, you will see the CO2 levels start to increase.

- Ensure you have at least 300mL volume of air. Once the levels start to taper off, take your reading. Should take less than 30 seconds.

- Once done, remove the needle from the package and place the needle cap on the needle itself to prevent accidental poking.

What is the Lifetime of a CO2 NDIR Sensor?

CO2 (carbon dioxide) NDIR (Non-Dispersive Infrared) sensors typically have a lifespan of 5 to 15 years. These sensors are designed to maintain stable performance over an extended period. However, their lifespan can be affected by various factors, including operating temperature, humidity, exposure to contaminants, and frequency of calibration and maintenance.

When do I Calibrate my CO2 Headspace Analyzer?

You should bump test before using the CO2 leak detector. Calibration should be performed in every 12 months. Calibration can be done by our lab or you can perform the calibration yourself with our video tutorials and purchasing the calibration kit.

Calibration Kit (sold separately):

Calibration T-piece & Tubing

Calibration Gas (CO2 balanced in N2)

Calibration Gas Regulator (C10)

Will a CO2 Gas Leak set off Carbon Monoxide Detector?

No, a CO2 gas leak will not set off a carbon monoxide (CO) detector. Carbon monoxide detectors are specifically designed to detect and alert occupants to the presence of carbon monoxide gas. Carbon monoxide and carbon dioxide are two distinctly different gases. Don't get confused.

How Does a CO2 Headspace Analyzer Work?

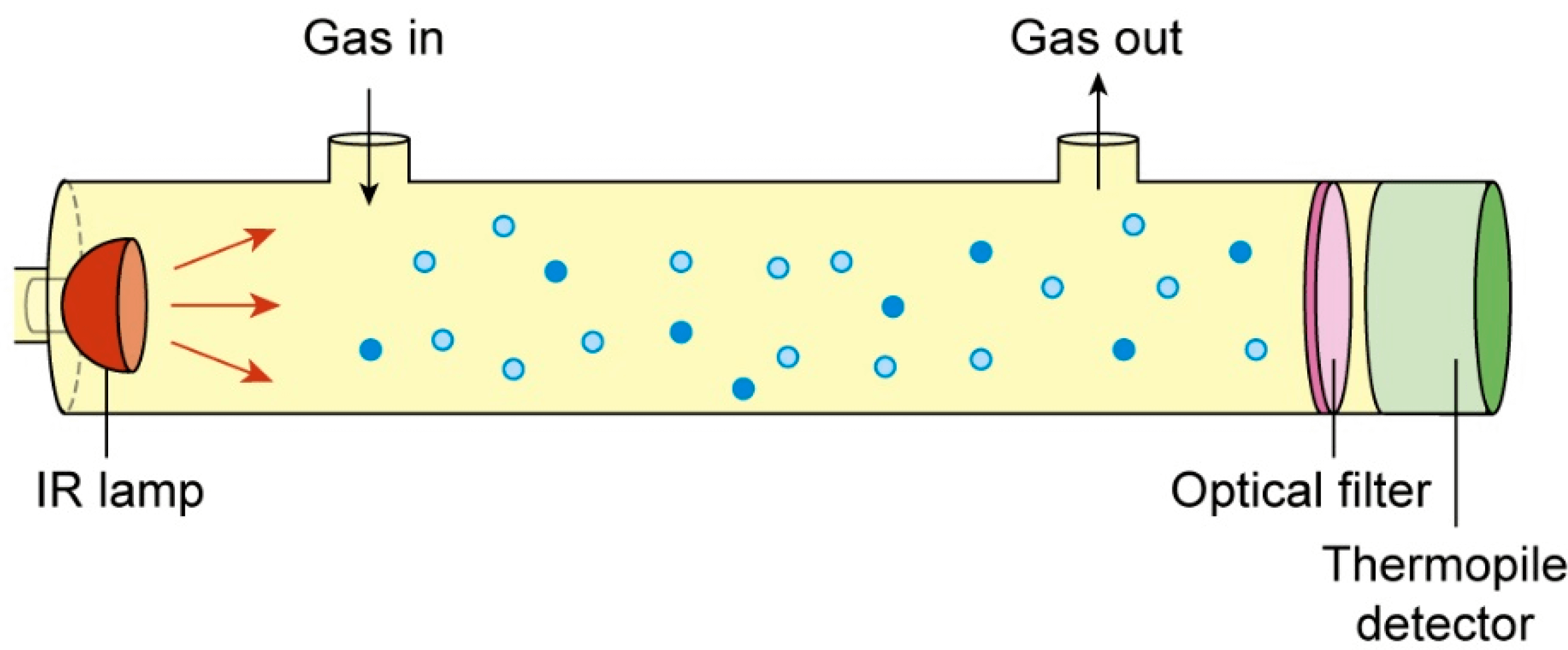

A CO2 headspace analyzer uses a sensing technology called NDIR to detect the presence of carbon dioxide gas in packaging gas. The principle behind its operation lies in the fact that CO2 molecules absorb infrared radiation at specific wavelengths, enabling the sensor to detect and quantify the concentration of CO2 in its surroundings. Here's a simplified explanation of how an NDIR CO2 sensor works:

- IR Light Source: The sensor contains an infrared light source, typically an IR LED or a lamp emitter.

- Gas Chamber: The sensor has a gas sample chamber, where the air containing CO2 is introduced via the help of a micropump.

- IR Sensor: Inside the gas sample chamber, an infrared detector photodiode or thermopile is present.

- Absorption: CO2 molecules have specific vibrational modes that resonate at certain infrared wavelengths. As the infrared light passes through the gas sample containing CO2, the CO2 molecules absorb some of the light energy at these specific wavelengths.

How Should I Store my CO2 Headspace Analyzer?

To ensure maximum sensor life and accurate measurements upon operation, it is recommended to store the Headspace Analyzer in a moderate environment with a humidity level of 50%RH and a room temperature of approximately 70F.

Difference Between a CO2 and CO Headspace Analyzer?

CO and CO2 are two different gases. Often these two gases are confused and mixed up between people and can be dangerous. CO2 is carbon dioxide and CO is carbon monoxide. Our CO Headspace Analyzer is also available.

How Does Film Packaging affect Headspace

Gases?

Achieving the optimal balance in food packaging between O2 and CO2 is challenging. This is because package permeation and respiration rates of the living produce can be challenging due to the limited selection of packaging materials.

The gas barrier properties of packaging materials play a critical role in determining the rate of gas exchange with the external environment and achieving tolerable levels.

However, the relative permeability of common films to carbon dioxide is often higher than that to oxygen, which can lead to package collapse for package atmospheres that benefit from carbon dioxide.

Additionally, films often fail to provide the desired oxygen transmission rates, high carbon dioxide-to-oxygen selectivity, and mechanical properties simultaneously.Active packaging components and films are being developed and designed to overcome CO2 and O2 selectivity challenges.

Can You Smell Carbon Dioxide Levels Detected By A CO2 Headspace MAP Analyzer

No, carbon dioxide is an odorless gas. While MAP analyzers can measure CO2 concentration precisely, humans cannot detect these levels through smell alone.

Conclusion

- A CO2 headspace analyzer is a specialized tool created to gauge the levels of CO2 gas present in food packaging.

- These analyzers are relatively expensive, with costs often reaching thousands of dollars.

- To obtain gas samples, headspace analyzers necessitate a destructive test that involves puncturing the food packet.

- For companies engaged in food production and packaging, a headspace analyzer plays a crucial role as it helps ensure product quality and compliance with industry standards.

- Proper care and maintenance are necessary to keep headspace analyzers functioning optimally.

- By providing food packers with quantitative gas concentrations, the headspace analyzer ensures that products consistently meet the expected quality control thresholds.

About The Author

Dr. Kos Galatsis ("Dr.Koz") is the President of FORENSICS DETECTORS where the company operates from the scenic Palos Verdes Peninsula in Los Angeles, California. He is a subject matter expert on gas sensor technology, gas detectors, gas meters, and gas analyzers. He has been designing, building, manufacturing, and testing toxic gas detection systems for over 20 years.

Every day is a blessing for Dr. Koz. He loves to help customers solve their unique problems. Dr. Koz also loves spending time with his wife and his three children, going to the beach, grilling burgers, and enjoying the outdoors.

Read more about Forensics Detectors here.

Email: drkoz@forensicsdetectors.com